UHP Pumps

Home / UHP Pumps

Gardella UHP Pumps

The experience of Gardella srl since the last 20 years on the market of water jet cutting, brings to develop the SpunkJet serie, the UHP pump that meets the needs of the market, but mostly the needs of the users.

The pressure intensifier SpunkJet is suitable to cut with pure water and abrasive too; a PLC may have its own control, or be interfaced to the CNC of the cutting table.

The design pressure of 4200 bar and high quality high pressure components can maintain a working pressure of 3700-3800 bar.

The main engine power ranges from 15 to 100 hp with a range from 1.2 to 7.6 L at peak performance.

- Extremely simple and rational to use.

- Easy to install and to maintain.

- Reliable with high quality components.

- Economic and accessible with low level.

- Prices of spares, the main voices that go to determine the cost per hour.

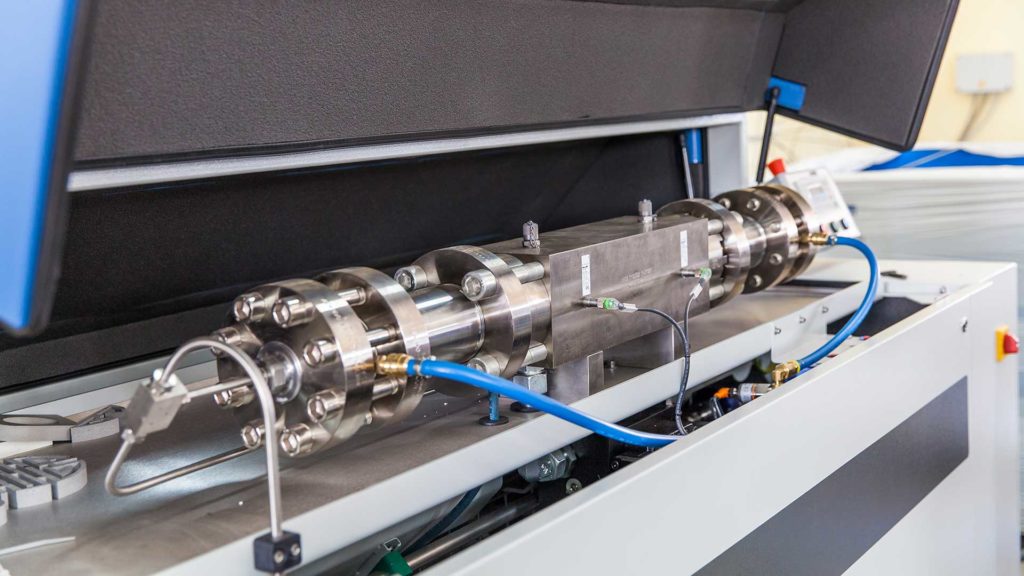

UHDE Pumps – Thyssenkrupp

![]()

Italian sole agent since 1999

- Compact design.

- Easy installation and commissioning.

- STANDARD series is immediately operational.

- Low investment and operating costs.

- Infinitely variable cutting pressure over the entire pressure range.

- Constant pressure amplitude, low pressure fluctuation.

- Minimized cycling load as a result of the long stroke.

- Autofrettage treatment of main high pres- sure components.

- Check valve cartridges with changeable valve seats.

- Exchange and removal of piston rod seals without disassembly of the hydraulic cylinder.

- Variable displacement axial piston pump with a highly dynamic controller saves energy costs due to optimized pressure and volume adjustment.

- Double-acting synchronous cylinder with easy to install plunger coupling.

- The installed oil-air cooling and filtration system permits permanent cooling and filtering of hydraulic oil.

- Material certifications for parts subjected to pressure according to standard EN10204 / 3.1.

- CE certification / declaration of conformity or manufacturer’s declaration according to EC guidelines 98/37/EC.

- Compliance with the directive for pressure vessels PED 97/23/EC.

- Installed automatic HP relief system.

6.000 bar technology

In competition with other processes such as laser and plasma cutting, waterjet cutting is increasingly developing into a real highperformance process. Nowadays, technology has advanced so much that multi-head and 5-axis systems are in operation, enabling cutting to be carried out on 3D components. Today mostly pressures up to 4,000 bar are used in waterjet or abrasive waterjet cutting technology. A further considerable increase in performance and therefore, increased productivity is only possible by raising the cutting pressure. Economic efficiency increases way above average when the cutting pressure is raised from 4,000 to 6,000 bar.

Convincing advantages

- Increase in power density by 83%.

- Up to 2 times faster cutting speed.

- Up to 40% reduction of abrasive mass flow.

- Up to 25% reduction in operating costs.

- Deeper cuts possible without the use of abrasive.

6.000 bar high pressure pumps

The development of 6.000 bar high pressure pumps is based on Uhde’s many years of experience in the production of

14.000 bar autofrettage pumps and 6.000 bar high pressure pumps for pasteurization plants (HPP).

In the year 2001 Uhde High Pressure Technologies was the first manufacturer to put a 2-stage high pressure pump system for an operating pressure of 6.000 bar into series production. A singlestage pump followed as a consequent improvement and resulted in the technically mature system being integrated into the new pump generation HPS/HPD.