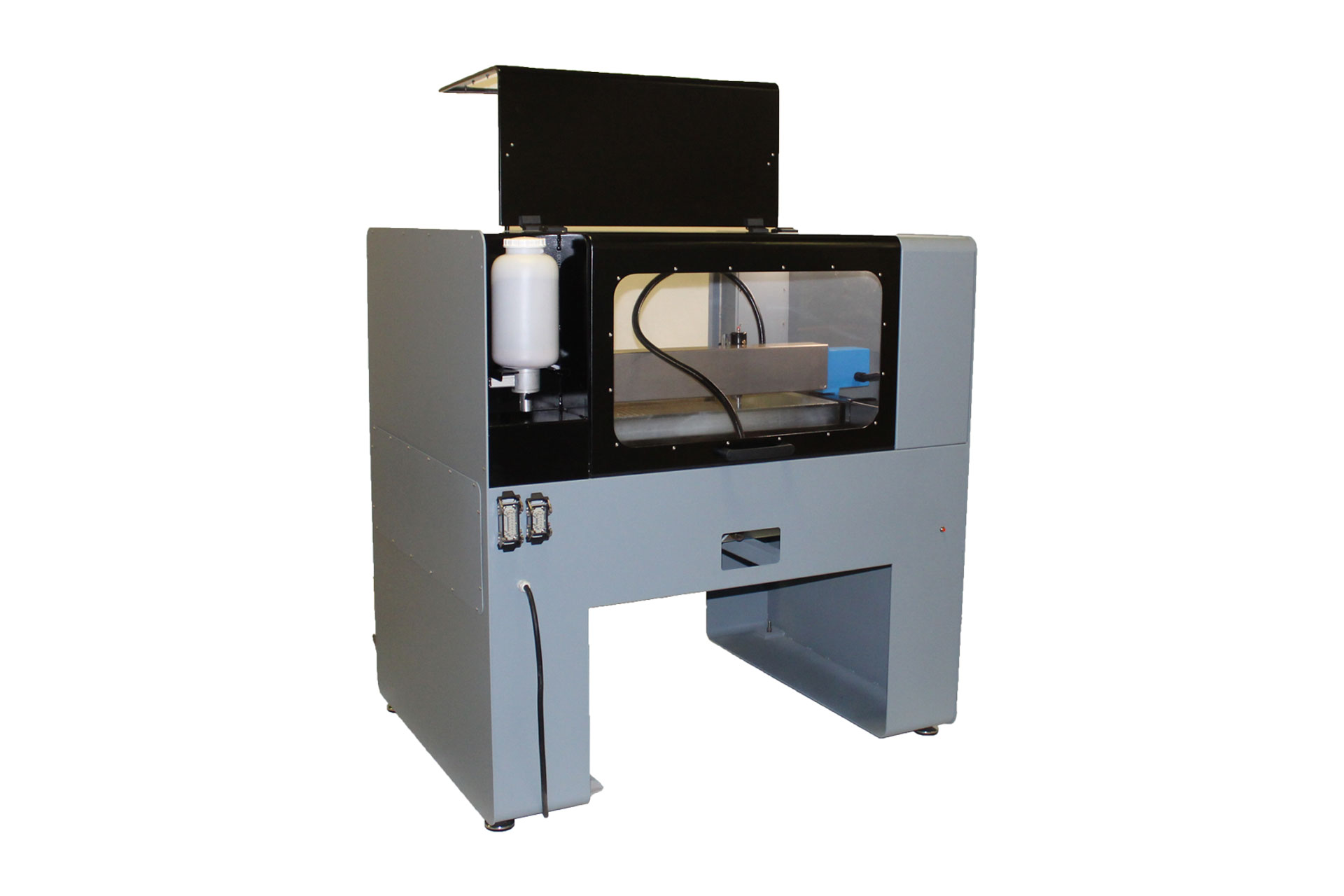

Miniwaterjet Radical

Home / Miniwaterjet Radical

From the experience gained over the past 15 years in the this field, Gardella srl has developed a range of water jet cutting systems, which have the following advantages:

- small dimensions that allow the plant to be placed in small work environments such as laboratories, workshops, etc.

- Integrated high pressure pump

- Extremely easy to use, accessible to everyone

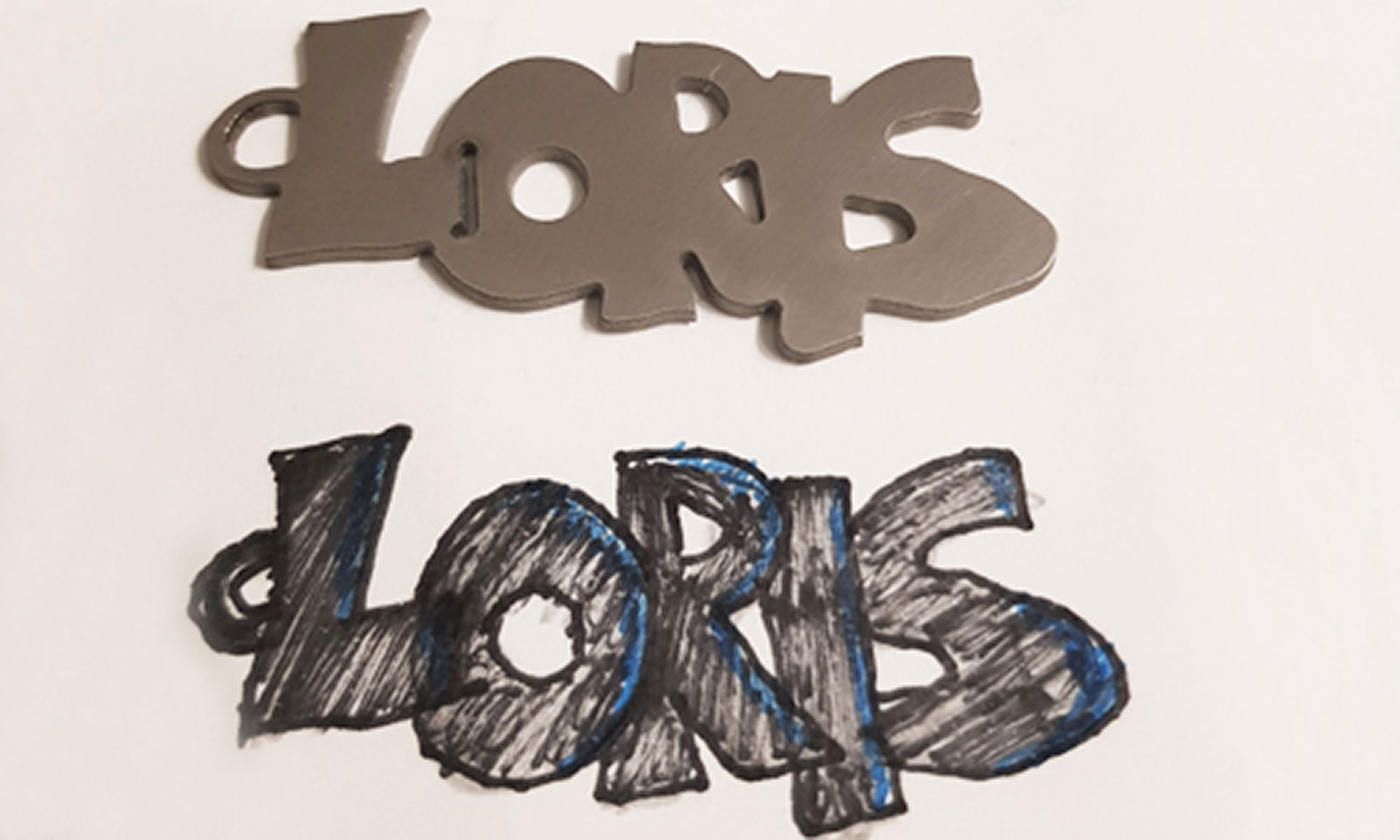

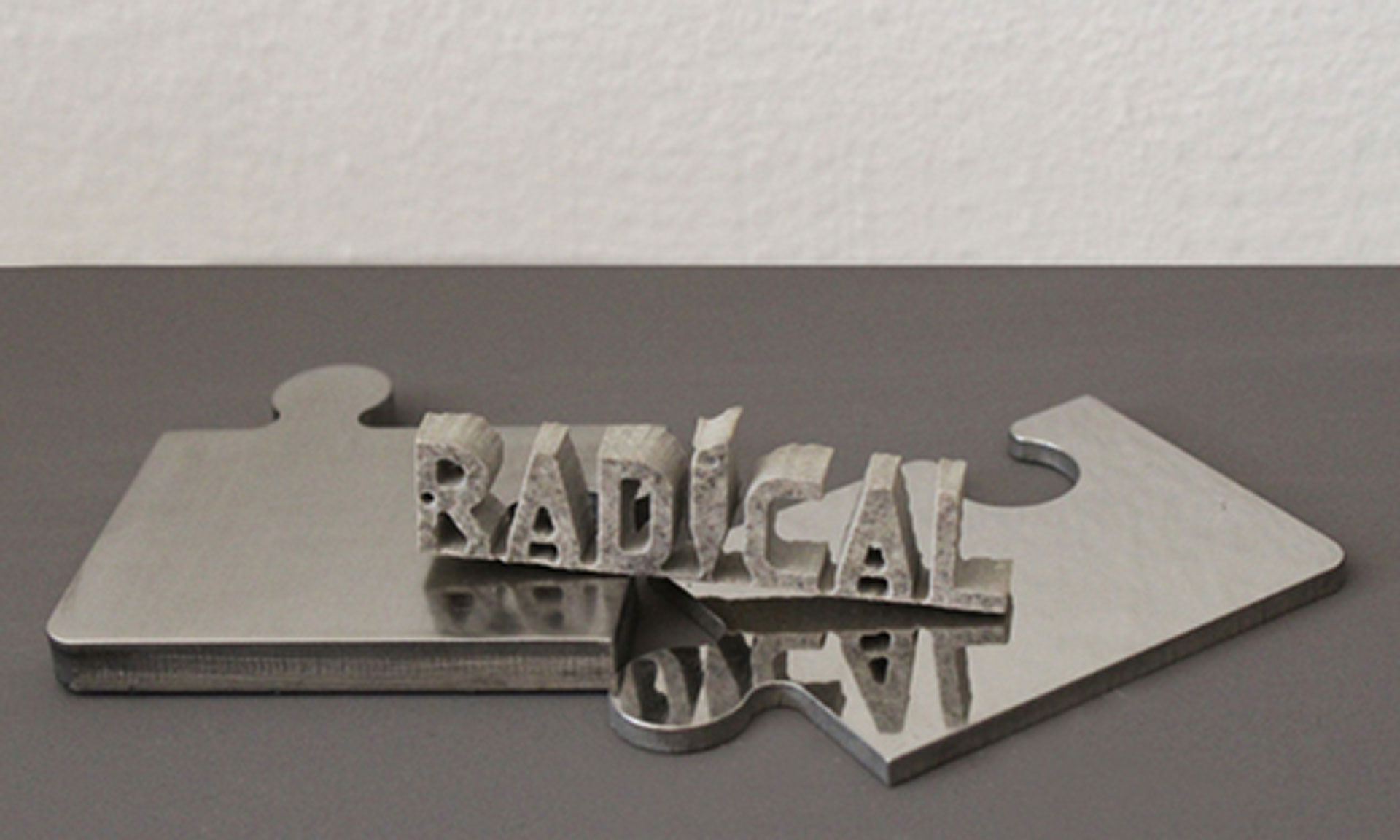

- Possibility of cutting pure water jet all soft materials up to a thickness of 100 mm

- (i.e. foam, leather, food, paper, cardboard, foam, fabric, polystyrene, insulating material, etc.)

- Possibility to cut all the hard-wearing materials up to a thickness of 50 mm

- (i.e. steel, aluminum, titanium, marble, granite, glass, stoneware, composite, carbon fiber, plexi etc.)

- Investment significantly lower than conventional waterjet systems, which are on the market

- extremely low cost per hours

- Long life wear parts

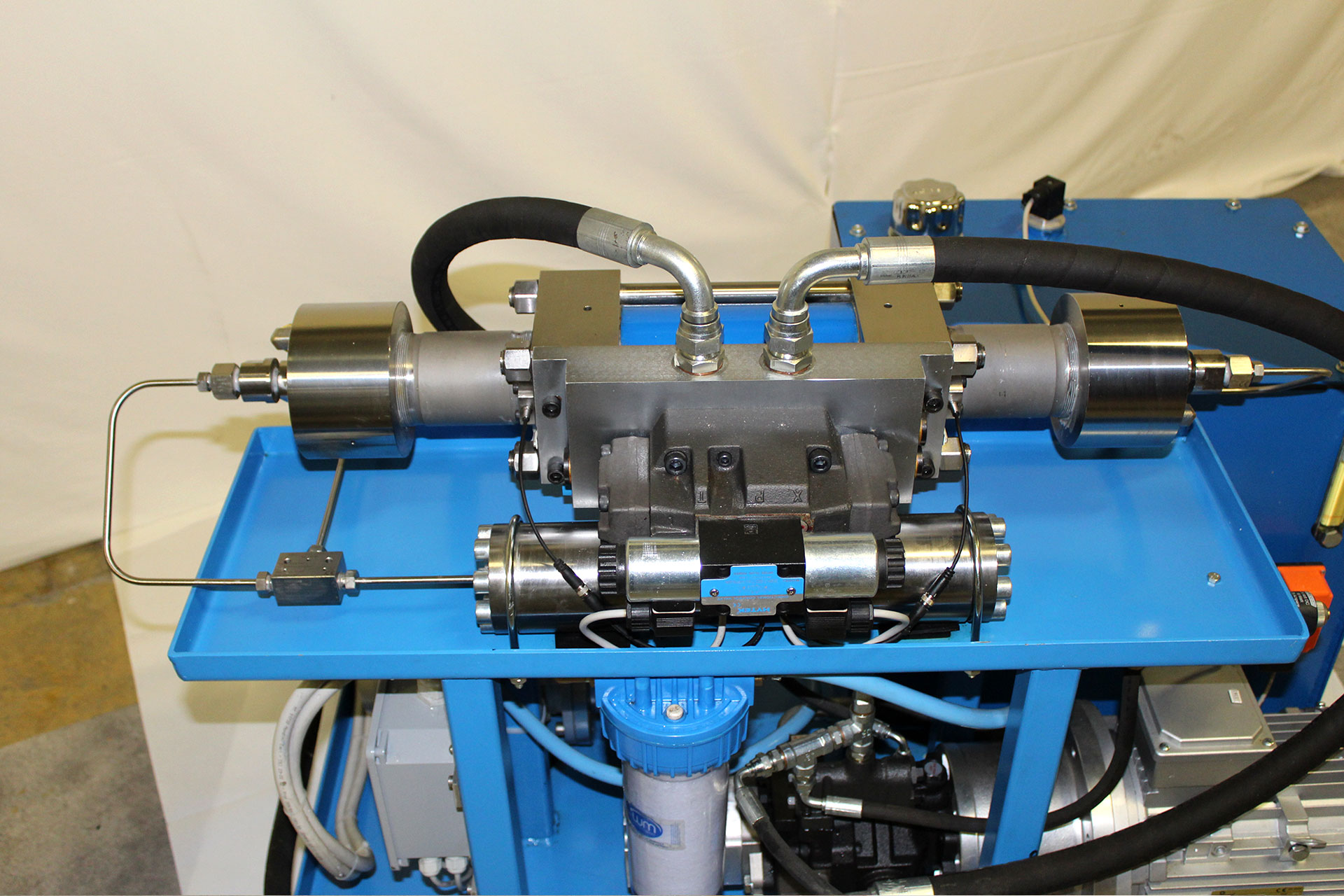

- three versions of high pressure pump, for all requirements, EASY, PROFESSIONAL and INDUSTRIAL

Technical features:

- working area min. X 500 – Y 500 mm

- working area max X 1500 – Y 2000 mm

- stainless steel tank

- work top with interchangeable grilles

- accuracy on cutting 0,1 mm

- speed of 20 mm/min.

- feeding and dosage abrasive system

- cutting head with integrated diamond orifice

- on / off cutting valve designed for 4000 bar

- high pressure pump components, pipes and fittings designed for 4000 bar

- prepared for abrasive removal system

- CNC with extremely user-friendly interface

- abrasive removal system (OPTIONAL)

- Z axis controlled (OPTIONAL)

- pressure pump upgrade (OPTIONAL)

MiniWaterjet is a viable alternative to traditional waterjet systems, if:

- you do not have enough space to accommodate a traditional cutting system

- if you have to cut small things and do not need a large plant

- if you want to contain the investment costs and you do not want to settle for a used machine

- if you want a system build for your specific needs.